The casing STL files can now be found under:

System reproduction

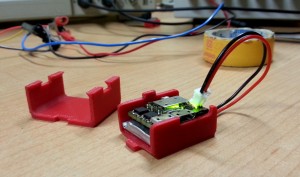

The casing is 1.5[mm] thick all around.

The outer dimensions of the casing are 23.2x31x13.5[mm].

The casing has a snap fit solution and does not require any screws or similar. This far, we have had the casings printed on a MakerBot 2 by myobjectify.com.

Archive for March, 2014

Casing STL files

Sunday, March 30th, 2014Brief technical summary

Tuesday, March 25th, 2014Below is a brief technical summary of the new boards/modules

- 4 MPU9150 9-axis IMUs sampled in parallel

- Atmel AT32UC3C2512C 32-bit floating point microcontroller

- ST SPBT2632C2A Bluetooth module

- Battery powered with charging via USB

- 4 layer 22.5x20x5.5mm PCB (excluding protruding USB connector)

- Module size, including 150mAh battery, circa 31x24x14mm (casing not final)

In addition we have also thrown in a flash memory (up to 64Mb) and a pessure sensor.

If you have looked at the photos below you may be wondering why there are two micro-USB connectors. The one which has a slot in the casing is a proper USB used for communication (if you don’t want to use the Bluetooth or simply want more data than the Bluetooth-link can handle), charging, and reprogramming with the bootloader. The one hidden inside the casing actually contains a JTAG interface for debugging and reprogramming. Micro-USB connectors are simply convenient small footprint connectors.

Design files released

Monday, March 24th, 2014Since we finally got a module working, I have now published the PCB design files under

Basic embedded software for the new modules is already available on sourceforge. However, significant updates, especially to the wireless interface, is expected in the near future. The STL-files for the casing I will publish as soon as it has gone through some more iterations.

By the way, the new boards goes under the name MIMU22BTv2 (MIMU=multi-IMU, 22=number of IMUs on front and back, BT=Bluetooth, v2=version 2). This is how it’s referred to in all config-files in the software.

Note that for some feature such as the memory and the pressure sensor there is still no software support for and they have not been tested at all. On the other hand they are not necessary for the core functionality or the boards, i.e. pedestrian tracking.

It’s working!

Monday, March 24th, 2014

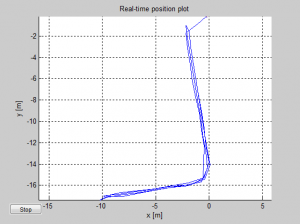

After what feels like a 1000 mounting attempts, we finally made one board of the first generation work! So 4 IMUs, wireless transmission, battery powering and realtime stepwise dead reckoning. To say the least I’m pretty relieved to see the whole chain working. We are still expecting updated versions of the boards but there are (should be) no changes to the schematic so hopefully they should work right out of the box.

The battery cables should later on be soldered straight into the board but due to further testing needs we didn’t want to do that. Consequently, you see the ugly solution with a JST connector and a pin header, and for the initial testing we had to go with electrical tape instead of the casing lid.

Above you see the first (actually second, since the first time I got about 5m and then the battery cable came off) tracking result with the unit taped to the forefoot and walking back and forth in the corridor two times. Note that Matlab is only summing up the step displacements and heading changes and most of the processing is done in the module.

Plenty of things remain to be done but at least now we know we will eventually have working modules!

Casing for the new modules

Sunday, March 16th, 2014While waiting for the new boards we have also started working on the design of the casing for the new modules. Surprisingly number of details to think about! Currently we are considering a snap-fit solution. A couple of guys from myobjectify.com helped me with the cad and printing. The day before yesterday I got a first crude print in my hand. The photos above show the size of the casing in comparison with an older unit and the casing with a battery and a partially assembled board in it (used for testing the wireless links).

OpenShoe is an open source project for creating an embedded foot-mounted

OpenShoe is an open source project for creating an embedded foot-mounted